In 2006, we revolutionised the cherry sorting process with an electronic vision grading system that quite literally doubled the effectivity of sorting colour, size and defects from the old mechanical ways. Fast forward 15 years and countless lanes of cherry vision grading installation completed and we’re again, making a dint in the industry with incredible results for Blueberry sorting.

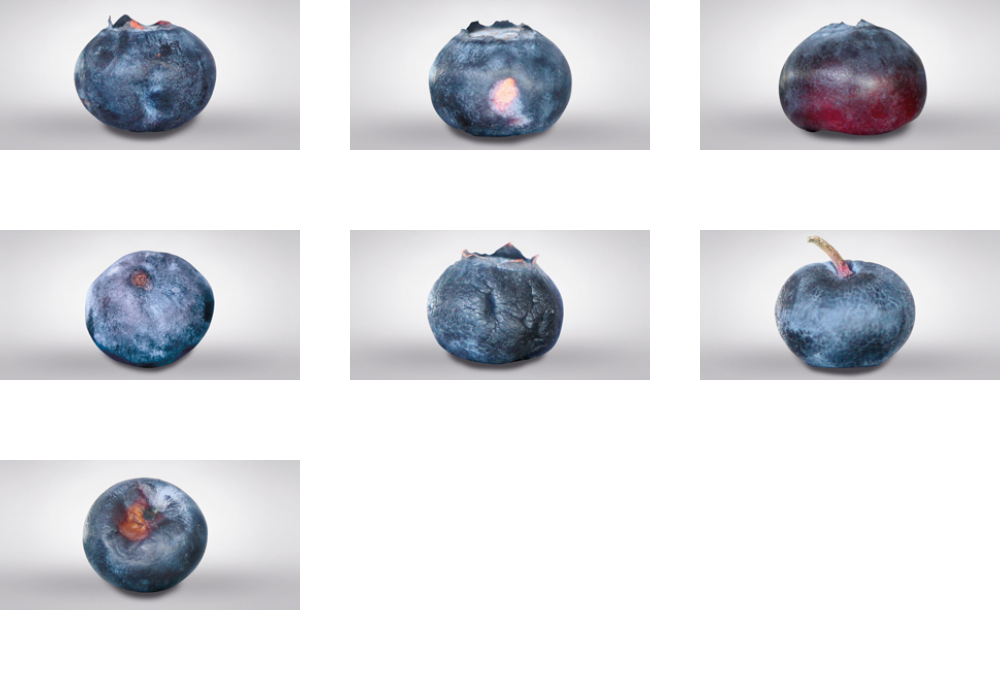

Traditionally, blueberries have been processed either by hand or by archaic mechanical machines that only achieved the simple process of getting fruit in to containers. Today, consumers demand more uniformity, consistency and a higher quality product. And the businesses that can meet those demands are leading the pack.