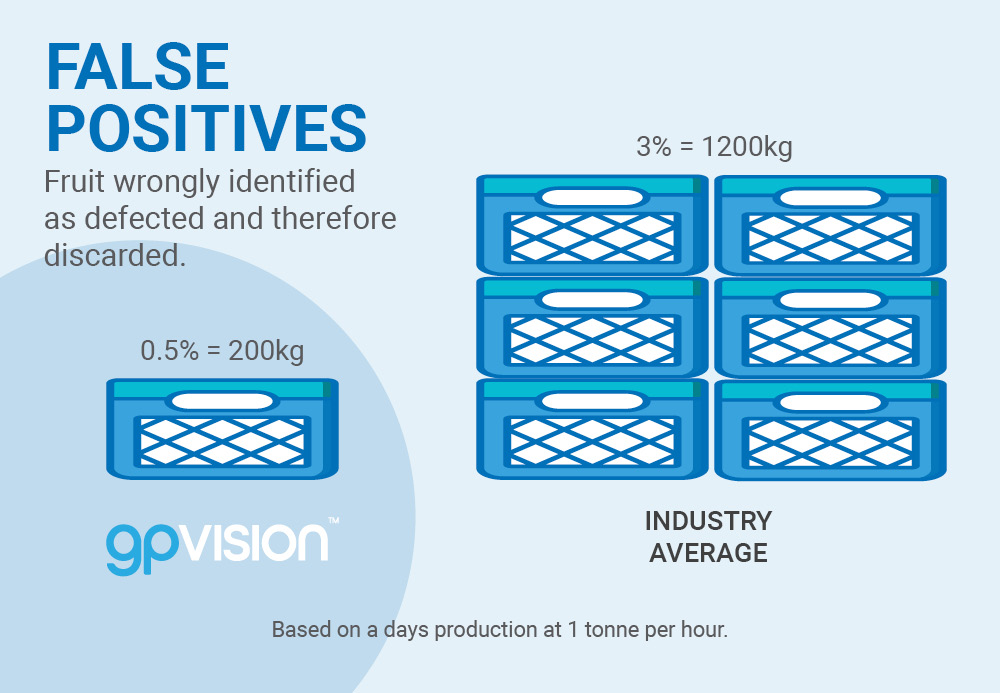

gpVision™ has quickly become the industry benchmark for vision sorting and grading for fresh produce and shellfish.

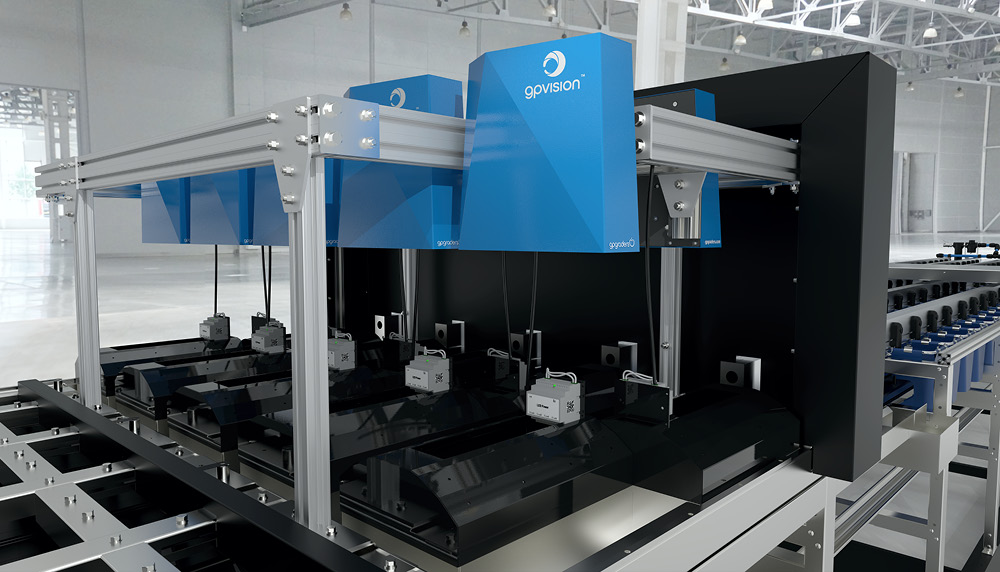

At the heart of our range of grading machinery is gpVision™, GP Graders’ proprietary vision sorting and analytical camera and software solution encapsulating ultra high definition (HD) cameras, advanced LED lighting, a real-time control unit and a complete firmware, software and user interface solution.

GP Graders is at the forefront of research and development in vision technology.

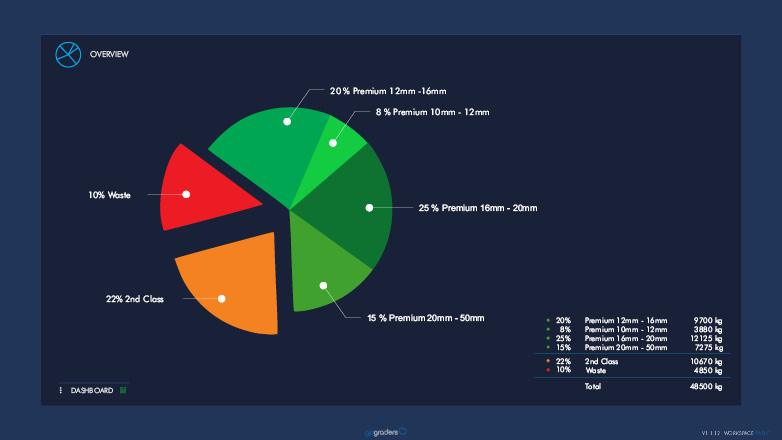

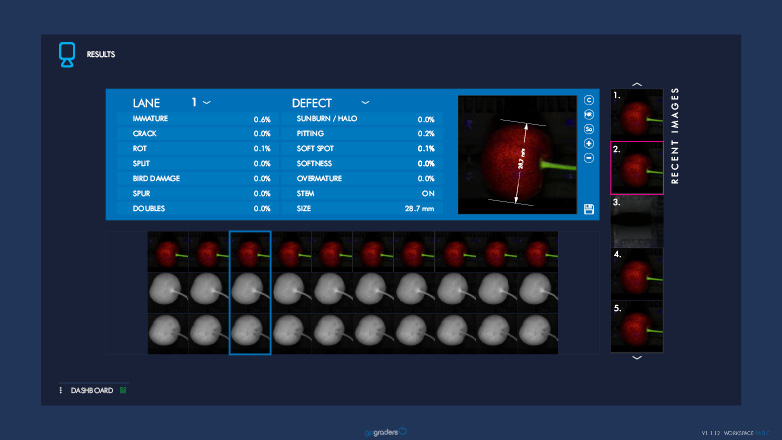

Truly ground-breaking development with machine learning is seeing gpVision™ redefine vision classification according to size, shape, colour classification and internal and external defect detection delivering unparalleled results in a simple-to-use environment with open-source code to export results to ERP systems.