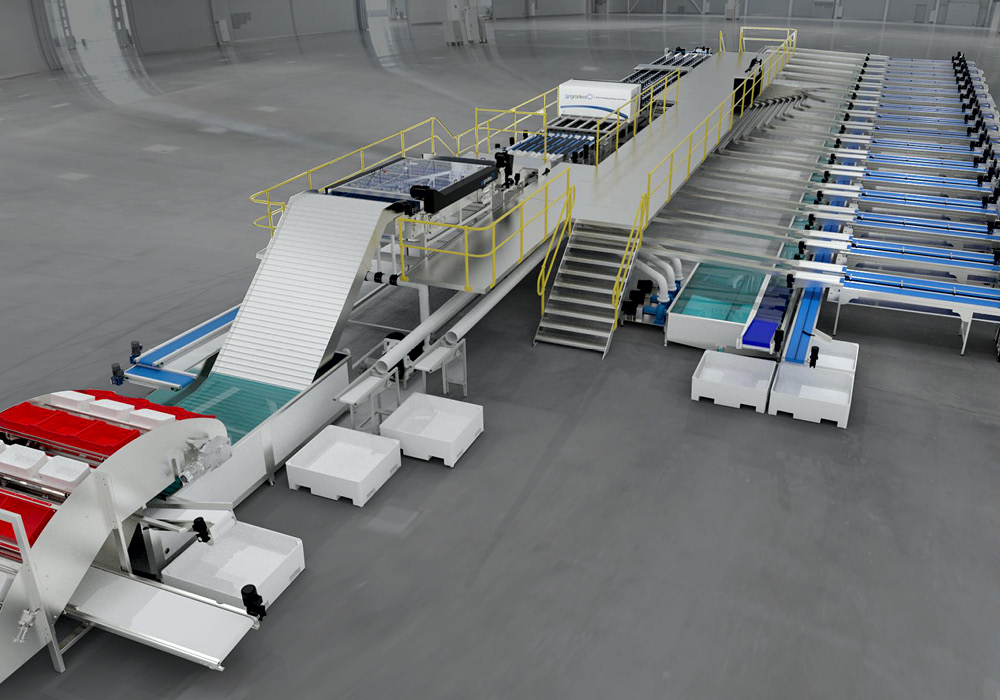

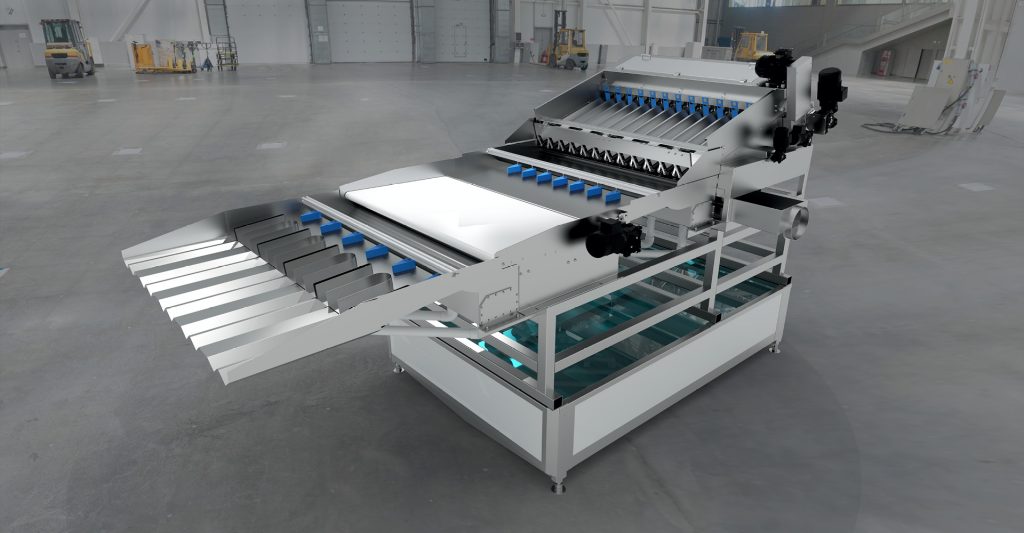

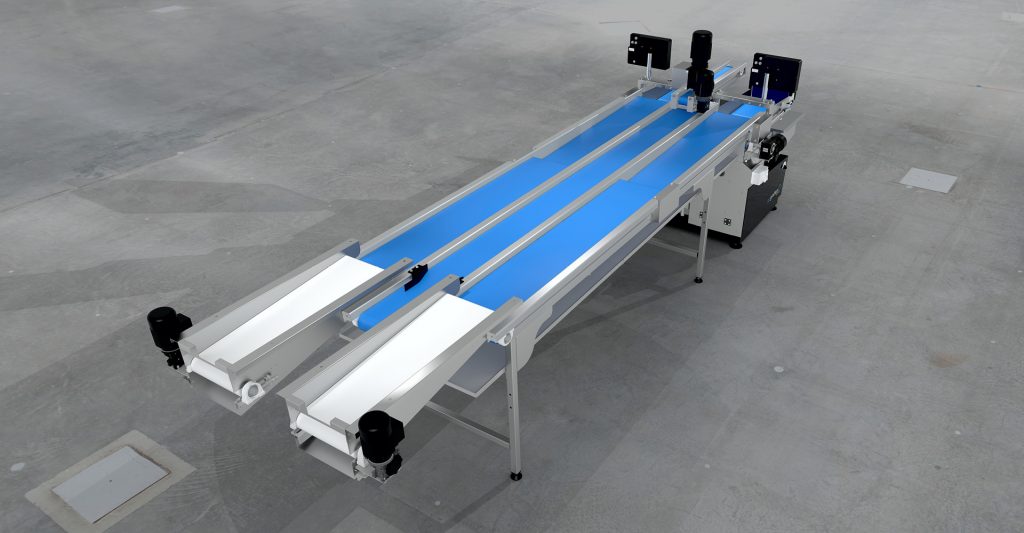

Our AirJet® Cherry Grader is at the forefront of the cherry machinery industry, as GP Graders are innovation and technology leaders. This is evident as GP Graders have been behind almost every innovation in the cherry machinery industry since 1987. The AirJet electronic cherry grader is the most technologically advanced sorting machine available today, and this cutting-edge technology helps you to achieve the best possible returns for your fruit, by dramatically reducing the sorting and packing costs, and providing perfect size grading.

Fast, gentle and accurate, GP Graders’ AirJet® grader sorts cherries at a speed of 30.2 units per second, or 600kg per lane per hour yielding high productivity while maintaining grading accuracy.