We’re proud to partner with so many exceptional agricultural businesses, enhancing the overall productivity and excellence of the fresh produce industry globally.

- 8 December 2023

- gpgraders

- No Comments

gpVision™ with MultiView™ is a Rainy Day Saviour

Certainly, we always need the rain, but the timing is far from ideal right now. As the southern hemisphere moves into peak season for cherries and stonefruits it’s unfortunate to see rain hit right when a good crop of cherries is at maturity, ready for harvesting and packing.

What is MultiView™?

A few years ago, we chatted with a grower in Tasmania and had a very frank conversation about cherry grading technology. The very simple fact was concluded that, no matter how incredible the technology of vision grading gets, if you can’t see the full surface area of the cherry, you can’t analyse it. And due to the stem of cherries exposing the bottom cracks to cameras is never guaranteed.

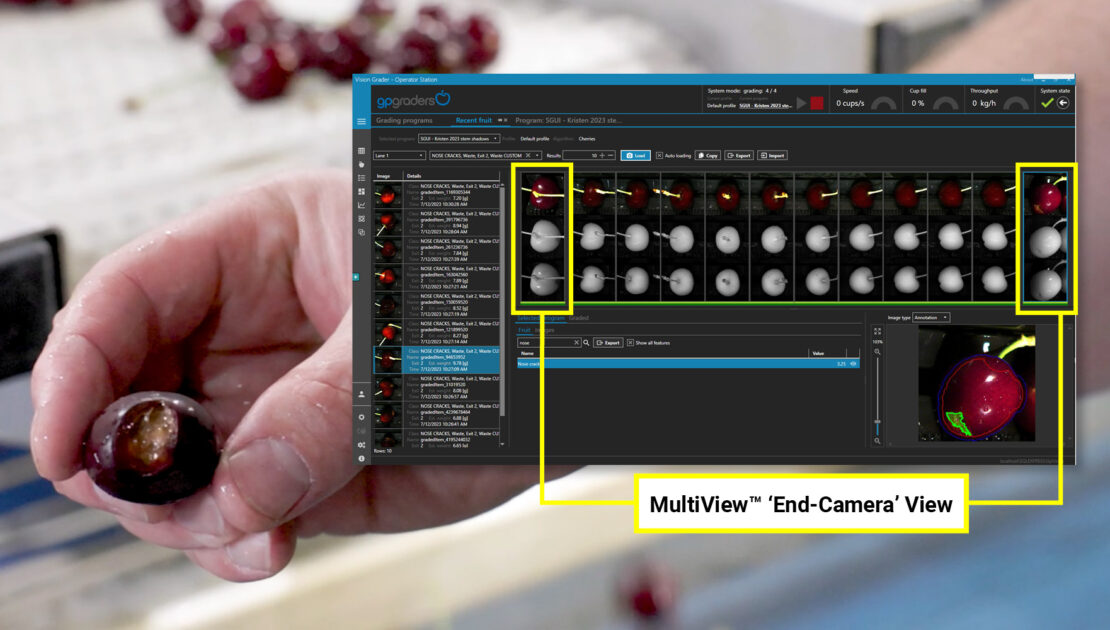

MultiView™ is an extension of the GP Graders fresh produce grading platform, gpVision™. The installation of an additional 2 sets of cameras per lane that are mounted at the front and rear of the usual ‘top-down’ camera box enables nearly 100% of the product surface to be captured and analysed. We call them ‘end cameras’. Installed at a specific angle, each box contains 3 cameras, bringing the total number of photos made for each piece of fruit to a staggering 36 images. This complete coverage ensures we can analyse the whole cherry, like never before, including the ability to now “see” the end cracks on the bottom of the fruit.

Why is MultiView™ saving the day?

Whilst the top-down cameras generate perfectly acceptable results, in the grading runs where the fruit is very poor (e.g. when the rains hit hard), the MultiView™ Camera System really starts to shine!

Being able to analyse almost every last millimetre of the surface of the fruit allows the intelligent algorithms in gpVision™ to go to work and identify problem fruit and remove it, well before any manual sorting is ever required. Seeing the bottom of the cherry is imperative to removing any further manual sorting. Now we see it all!

In the unfortunate situation where packout percentages fall below, say, 60%, it’s confidence-inspiring to know that having an accurate grading system prevents a blowout in labour costs, just to salvage sellable fruit.

gpVision™ is the new standard for fruit grading.

When we made the bold decision to develop our very own complete grading solutions, from cameras and electronics to firmware and software, we had two clear goals:

Make it the best and most accurate in the market, and make it easy to use.

To date, we’ve had fantastic feedback on the usability of the new user interface. Users have said the system is more intuitive and considerably easier to adjust to maximise accuracy in grading results. In fact, anyone can use and get elite results with just a few hours of training.

When it comes to accuracy, it only takes a moment in front of the waste bin to realise the work that gpVision™ is doing. Every bit of fruit coming out of the waste exit belt is one less piece of fruit that a manual sorting person needs to take out.

Sufficed to say, we know our grading solution is delivering superior results. And our customers have told us so…

What our Customers are Saying

One cherry grower commented that with the monumental labour shortages and challenging weather conditions, his season was ‘absolutely saved’ by gpVision™. Fruit that was battered by rain and extreme heat meant he would not have been able to process the volume of fruit picked. The new graders’ productivity and the manual sorting work avoided made the season viable again and the investment well worthwhile.

“With the upgrade to gpVision we were able to pick fruit from the orchard that we otherwise would have left on the trees because we had the confidence our grader could salvage enough good fruit to make it worthwhile.” – Spreyton Fresh

“The cameras have lived up to what they said they would. So far we have had no rejection. The QA has been no less than 90% and our staff costs are down, so all and all it was the best decision we made this year.” – BiteRiot

gpVision™ is Proving Again, to be a Wise Investment

The advent of MultiView™ emerges as a timely solution, particularly during seasons with challenging weather conditions. The system will help to maximise packout percentages and help to prevent a surge in the labour costs associated with manual sorting.

The commitment to creating a complete grading solution with a user-friendly interface and unparalleled accuracy underscores gpVision™ as the new standard for fruit grading. The system’s ability to detect battered fruit and therefore enhance overall productivity reaffirms its significance, making the investment in gpVision™ a worthwhile and season-saving choice for growers and packers.