We’re proud to partner with so many exceptional agricultural businesses, enhancing the overall productivity and excellence of the fresh produce industry globally.

- 3 March 2024

- gpgraders

- No Comments

The Synergy of Software and Mechanicals Makes a Significant Difference in Cherry Sorting

Vision sorting technology continues to make giant leaps forward in the sorting and grading of fresh produce. The introduction of Artificial Intelligence (AI) to distinguish a greater range of fruit defects with greater accuracy, improved camera technology, faster computer processing, flexibly written software to provide more data and it all wrapped up in a simple-to-use environment make the future of cherry grading look more promising than ever!

High-accuracy vision sorting relies on a multitude of factors.

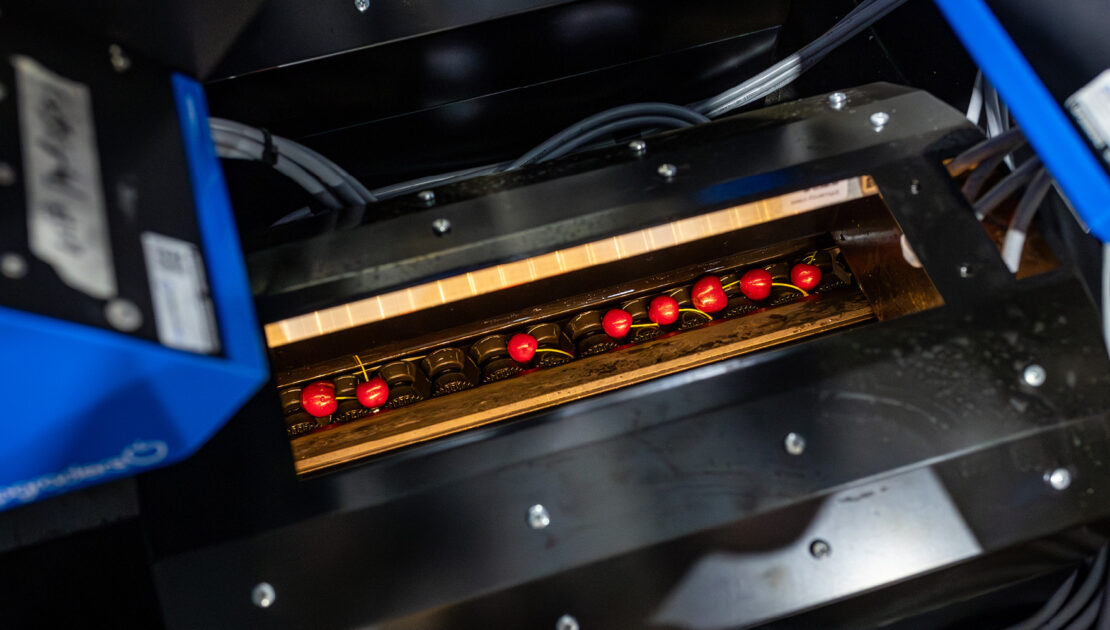

Software is an important element but so too is camera positioning, the design and placement of mirrors and filters, the mechanical elements carrying fruit under the cameras, fruit rotation speed, and the electricals that make these components work together. This is often where the true smarts of the grading outcome are found as you simply can’t have one effective element without all elements working in synergy.

One key reason for the rotation system, for example, to be set up well is that software can only assess what the cameras can “see”. So the mechanics must work perfectly to present the full surface area of the fruit to be “seen” by the cameras. If any area can’t be seen then it will not be analysed and hence, missed. Sure, you can have great software and AI features but if you don’t get the fruit rotating under the cameras to show off its full surface then it’s a waste of time and you will end up with too many defects not presenting to the cameras and thereby getting carried through to the packing belts, if you have packing belts at all.

The mechanics of rotating cherries are complex and involve multiple stages of readiness before they are rotated effectively under the cameras. It is a critically important process as it can be the difference between removing 95% of defects or 60% of defects. This then translates to more staff sorting fruit before packing which is what the investment in sorting electronics was trying to eliminate.

Profiting from the investment.

This past season in both Chile and Australia the cherry crops were hit by multiple early rain events. Long sustained rain which is the worst for cherries at maturity, it caused immense damage. With crop losses down to 50% most farmers would have walked away and not harvested, as the economics of picking, sorting and packing wouldn’t have stacked up. But this year they did harvest, and that’s thanks to the newest version of software being installed along with mechanical improvements that were made last year. Those that invested reaped the returns and it was a significant payoff. Having end cameras fitted, improvements to the mechanics under the rollers and a few other enhancements, packers with gpVision™ and the MultiView™ platform were packing down to a 50% crop harvest and still profiting from it.

This year, a customer in Chile who packed on a machine fitted with gpVision™ and the MultiView™ platform, achieved the highest box price in China due to the exceptional packout quality. In Australia, there was only praise from buyers of fruit coming off machines fitted with gpVision™ and the MultiView™ platform.

The vast majority of Australian cherry packers use GP Graders machinery and the majority of those using gpVision™ have now upgraded to the MultiView™ platform. Now’s the time to discuss with our team how this investment could be the difference between a profitable harvest season or a year you don’t want to talk about.

Get in touch today.